What is Bitumen?

Types Of Bitumen?

Bitumen Uses?

Properties of Bitumen?

Bitumen is black material that is consumed from 4000 years B.C. Its previous Latin name was PIXTU-MEN and these days bitumen and Asphalt is used as its name. Its main usage is in roads and streets, asphalt and insulation. One in all the kinds of bitumen that is employed additional is refined bitumen made in refineries. Additionally, a form of tar is made from coal. There are natural bitumen mines in nature which need to be refined. Bitumen are divided into 2 main teams in usage: paving grade and roofing grade. With chemicals, bitumen components are divided into 2 teams of Hydrocarbure, Asphalting, and Maltin. There’s 5-30% Asphalt in in bitumen that causes the hardness of the bitumen. Maltin is created of grease and rosin.The heaviest derivative that is separated from crude oil within the vacuum distillation unit is that the residue of the vacuum distillation that is briefly referred to as vacuum bottom or VB. This residue is that the main feed for the bitumen manufacturing unit. During this unit, v.b is oxidized using air. Oxidation continues as long because the feed reaches normal properties of bitumen like the penetration range and softening purpose (melting temperature). Since the temperature of bitumen is increased in oxidation method, the output of reactor passes through a cooler so is sent to storage tanks. By regulating operational variables like the temperature of reactor, residence time within the reactor, and also the ratio of air to feed it’ll be possible to supply totally different grades of bitumen for various consumptions like road and industrial types. Moreover, adding some proper additives permits the United States to supply changed bitumen like polymer changed bitumen (PMB) that is very resistant in heavy traffic and bad climatic conditions. Another bitumen product is bitumen emulsion that is bit by bit subbing cutbacks for its environmental privileges as well as energy consumption savings.

Bitumen Grades

Bitumen is available in a variety of grades. Specifications vary to meet the needs of the consuming industries and are based on a series of physical tests that define the safety, solubility, physical properties and durability of bitumen. The physical properties are designed to define performance characteristics that are required under the climatic and loading conditions that the bitumen will experience in service. Bitumen is graded according to standardized testing methods. These tests also give rise to two commonly used terms which describe the method of measurement, rather than a type of bitumen:

Cutback Bitumen

Penetration Graded Bitumen

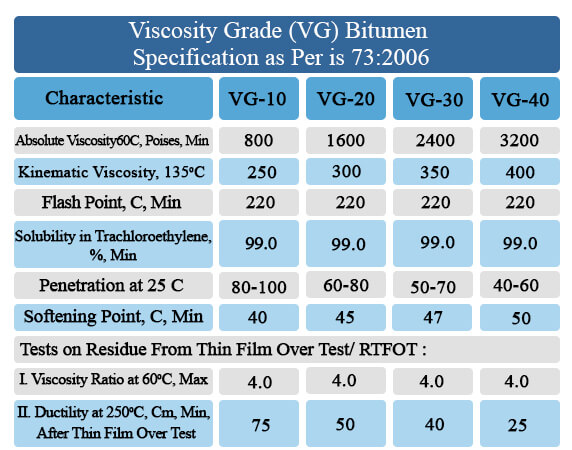

Viscosity Graded Bitimen

Oxidized Bitumen

The density of bitumen

The definition of specific gravity than the weight of a certain volume of bitumen 60/70 within the bitumen by weight of water outlined within the such temperature.

Tools needed: pycnometer and Balance Pycnometer first cleansed so our weight. As molten bitumen 60/70 is poured into the pycnometer and wait reaffirm the air bubbles out. Then we pycnometer containing bitumen weight and therefore the weight of empty pycnometer and fill, to determine the worth of our bitumen weight. Water conjointly does a similar steps and water weight gain.

Specific gravity bitumen is achieved by the following equation:Bitumen specific gravity = X / YX

The weight of the pycnometer filled with tar and no air bubbles weight minus the empty pycnometerY Weight pycnometer with water minus the weight of the empty pycnometer.

Penetration Bitumen grades are available:

Bitumen 60/70 80/100 85/100 40/50 90/130 and 160/220 is black semi solid heavy hydrocarbon which is the last product of extract tower which by cool down of ambient temperature will convert to solid. With increase of temperature the bitumen will become semi solid and then liquid. Main content of bitumen us hydrocarbon with high molecular weight contenting oil, resin and asphalten.

Packing of bitumen:

Available packing is new steel drum, polybag, jumbo bag, Bulk bitumen, Bitutank.

Bitumen in steel drum: Size of drum bitumen is 110, 150 and 185kg and our bitumen is available just in new steel drum

Bitumen in polybag: Polybag is a composite bag with different two sizes of 25Kg and 50Kg available in loss and palletized packing.

Bitumen in jumbo bag: Jumbo bag should be stuffed in container only one layer and each jumbo bag is 850Kg.

Bitumen in bulk vessel: We are able to supply bitumen in bulk starting from 1000MT up to 36000MT.

Bitumen in bitutank: Bitutank and bitutainers should be arranged by our customer and we can support bitumen buyers up to FOB

Bitumen manufacturing process

Bitumen is produced from selected crude oils through a process of fractional distillation. The crude oil is heated to temperatures of between 300 and 350 degrees Celsius and fed into a distillation column allowing the lightest fractions of the crude to separate, through vaporization, from the heavier fractions, which remain liquid. The higher boiling point fractions are then drawn – off via a heat exchanger and enter a vacuum distillation column. This process produces a short residue that is used to manufacture several grades of Iran bitumen.The pressure and temperature conditions within the vacuum process will determine the hardness of the short residue, and as such the grade of Iran bitumen produced. The short residue may be further modified by air blowing in which air is passed through the residue at temperatures of 250 – 300 degrees Celsius.

Quality of Bitumen:

We are doing several test on bitumen before export , some of the test is as below

Penetration test of bitumen

Specific gravity of bitumen

Softening point of bitumen

Solubility of bitumen in TCE

Ductility test on bitumen

Flash point on bitumen

Spot test on bitumen

Drop in penetration of bitumen after loss on heating

Change of mass

Retained penetration

Ductility at 15C

Bitumen Price

Comments Off on Bitumen with 251 visit