What is Bitumen Enamel?

Bitumen enamels and suited primers to be used in combination therewith are described in Specification for Bitumen-based Hot-applied Coating Materials for Protecting Iron and Steel, Including Suitable Primers Where Required, BS 4147: 1980 by the British Standards Institution, said matter hereby been incorporated in the present specification. The same applies to examples of tar enamels and suited primers described in Specification for Coal-Tar-Based Hot-applied Coating Materials for Protecting Iron and Steel, Including Suitable Primers Where Required, BS 4164; 1980, also by the British Standards Institution.

Tar enamels, such as for instance, coal tar enamel, are old and well-known pipe coating materials possessing several excellent properties, inter alia an outstanding protecting effect against corrosion. However, the material is gradually growing outdated, partly due to its environmental drawbacks and partly due to the difficulty of providing the raw materials of the correct quality. In addition, the use of tar enamel is encumbered with draw-backs relating to the production thereof because the properties of the tar enamel may change during the production which involves repeated return pumping’s, reheating and flood coatings, where it cannot be avoided that some of the ingredients of the enamel evaporate.

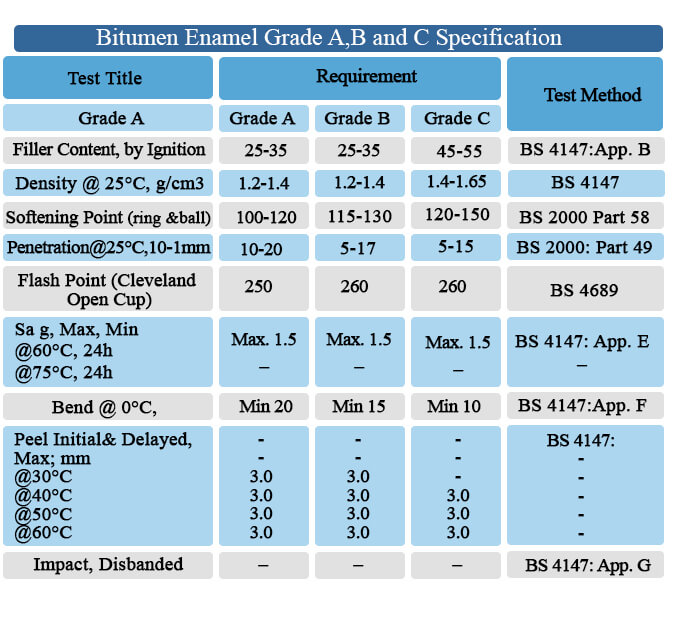

Bitumen Enamel Specification:

Bitumen Enamel Application:

We are Manufacturer of Bitumen Enamel Products

Enamel Coating

A typical tar enamel to be used for protection against corrosion contains tar of the quality 105/15, 105/8 or 120/5 according to BS 4164: 1980 in a quantity of 65 to 75% by weight together with filler in a quantity of 25 to 35% by weight.

Enamel Pipe Coat

Bitumen enamels are well-known and appreciated pipe coating materials presently used to an increasing extent instead of coal tar enamel. Most of the pipelines for oil and gas in the North Sea are coated with bitumen enamels. The material is often recommended, but has also been criticized for instance due to poor bitumen quality in connection with the oil crisis in 1972 to 1973. It is of vital importance that the correct bitumen quality is used, such as for instance bitumen 115/15, and that the supplies are reliable.

Anti-Corrosion Bitumen Enamel

A typical conventional bitumen enamel to be used for protection against corrosion contains bitumen of the quality 115/15 according to BS 4147: 1980 in a quantity of 65 to 75% by weight together with 25 to 35% by weight of filler, most typically approximately 70% by weight of bitumen and 30% by weight of filler. The addition of filler is usually determined by the melting point of the bitumen used. A conventional bitumen enamel is heated to 220 to 230C while being stirred and applied in a layer of a thickness of 5 to 7 mm.

GB-PS No. 1538267 discloses a process for coating a pipe comprising applying to the pipe a bituminous composition comprising from 80 to 99% by weight of bitumen and from 1 to 20% by weight of a block polymer having the general configuration: A-B-(-B-A) n

Wherein each A is a thermoplastic polymer block of a monovinyl aromatic hydrocarbon or a 1-alkene, B is an elastomeric polymer block of a conjugated diene or more than one 1-alkene, and n is an integer or a hydrogenated derivative of the block copolymer.

However, the above coating process has not yet been accepted for industrial use due to insufficient bonding of the bituminous composition to the pipe.

Bitumen Enamel

Bitumen enamel is corrosion protection material in onshore and offshore.

Long Term Corrosion Protection

The best adhesion to steel provides a track record of long term corrosion resistance.

Recommended for pipelines designed to convey water, gas, oil or any other fluid when the continuous temperature of the fluid being transported does not exceed 70C (I 58°F) *

Bitumen enamel is safer and more environmentally friendly system, then coal tar enamel.

Engineered Solutions

Advanced manufacturing techniques allow Bredero Shaw to supply AE coatings with varying grades of asphalt enamels and inner and outer wraps along with a thickness as per your design specification.

The system can be applied to various pipe diameters from 90 mm (3.5) to over 1200 mm (48).

Proven Performance

Extensive track record of excellent performance in over 8,000 enamel pipe coating projects

AE coating for large projects can be performed at multiple Bredero Shaw locations to improve logistics.

High capacity within the Bredero Shaw plant network allows the client to benefit from single

For additional standards and specifications with which this product complies, please contact your Bredero Shaw representative.

What is pipe coating bitumen enamel?

We are an Iranian producer of bitumen enamel is a pipe coating product applied durable coating based on bitumen enamel which is a type of modified bitumen that has been successfully used for many years for corrosion protection of steel pipes.

The advantage of bitumen enamel:

Bitumen enamel has excellent adhesion to steel provides a track record of long term corrosion resistance.

Bitumen enamel used for pipelines designed to different application such as water, gas, oil or any other fluid when the continuous temperature of the fluid being transported does not exceed 70C (I 58F)!

Bitumen enamel is safer and more environmentally friendly system, then coal tar enamel because of the acidity of tar.

Bitumen enamel pipe coatings with varying grades of bitumen enamel and inner and outer wraps along with a thickness as per your design specification.

The enamel can be applied to various pipe diameters from 90 mm (3.5to over 1200 mm (48).

Enamel pipe coating bitumen based material is used for many years across the world.

How to Use Bitumen Enamel?

BITUMEN ENAMEL should be broken up into small pieces and put into the kettle. Heat should be applied slowly until there is a quantity of melted Enamel on the bottom of the kettle. Kettles used previously for bitumen should be thoroughly cleaned before use.

The quantity of enamel remaining in the kettle from previous use should not exceed 10% of the fresh charge. The maximum temperature of Enamel in the kettle should never exceed 250 C and the Enamel in the kettle should be stirred constantly during the use. The normal application temperature of Enamel is related to its grade but it is normally between 220-240 C.

Enamel above this temperature should be rejected. Enamel should not be applied to the primer pipe when the metal temperature is below 7 C and care should be taken from the pipe is free from dust, oil and moisture.

Comments Off on BITUMEN ENAMEL with 710 visit