What is Bitumen Emulsion?

Bitumen emulsions, usually having a relatively low average particle size, can be continuously and speedily prepared by a process comprising feeding emulsion components into the first of at least two static mixers, arranged in series. The product is passed from the first mixer to the second mixer maintained at a temperature lower than that prevailing in the first mixer and below the boiling point of water. The final emulsion product is obtained from the outlet of the second mixer.Bitumen emulsions of up to 70 wt. Bitumen of mean particle size of from 2 to 8 microns are also described.

Description of bitumen emulsion:

This invention relates to bitumen; emulsions and a process for preparing them. Bitumen emulsions are well known materials useful in road-making and for other purposes. Their attractions are ease of handling, because of their lower viscosities than the starting bitumen, and their ability to be applied at lower temperatures in spraying etc techniques. There are no environmental problems because in use when the emulsion breaks and the water present evaporates to leave a film of bitumen where required.

There are two main methods currently used in the preparation of bitumen emulsions. The first employs a colloid mill and the second a centrifugal pump.

In the process employing a colloid mill, bitumen, water and emulsifier are emulsified at a high shear rate. The process is continuous, but to obtain an emulsion in which the mean diameter particle size of the bitumen is at an acceptable level, then for any given pump there is a limit on throughput in order that a sufficiently high shear rate is obtained. Furthermore, the process is conducted at atmospheric pressure and in order for the emulsion product to emerge at a temperature of less than 100C. Then it is found in practice that bitumen cannot be fed into the emulsifier at more than 140 C. Higher temperatures for the bitumen feed require lower temperatures for the water feed. This causes skin-hardening of the bitumen on the contact of the two feeds and emulsification becomes very difficult. This temperature factor places a limitation on the types of bitumen, which may be employed in bitumen emulsion manufacture by this route. A recent development, employing pressures slightly greater than atmospheric, involves cooling the product so that it can emerge from the mixer at below 100C. This entails extra equipment and is difficult to control.

The second known method employs a centrifugal pump which, in practice, cannot normally be operated under pressure. Again, this process has the drawbacks of the above-referred to colloid mill process and, furthermore, is essentially only a batch process. The water phase has to be continually recycled, whilst the hot bitumen is added little by little. The resultant emulsionproduct has a fairly wide particle size distribution and this leads to unevenness in the surface obtainable in the use of the product.

Bitumen emulsion SS1:

Anionic emulsion bitumen SS1 is two phases of water and bitumen, which is not possible to mix and first inter phase is inside of outer phase. Particle size of emulsion is 0.1 to 5 microns. In normal conditions and without emulsifier the two parts of emulsion SS1 are unstable and quickly will segregate. By adding an emulsifier into water and bitumen that is an alkaline salt with Ammonium Salt in a high-speed mixer at ISO condition making bitumen SS1.

Percentage of emulsifier is 3-5% and total water content is between 30-50%. By adding Emulsifier to bitumen and water we put anionic electron on the material and each particle of bitumen became like as a circle with a size of 0.001 to 0.01 mm and become floating in water. Using bitumen SS1 is environmentally friendly since any flammable material or kerosene is not used and firing of the bitumen during the usage would be zero.

This kind of anionic bitumen has more adhesive to building material which is contain lime

Application of bitumen SS1

It is used for cold asphalt in cold or humid or sealing.

Packing of Bitumen SS1

Packing of emulsion bitumen 208Kg drums in new thick steel on a pallet to prevent any leak inside of the container also bulk in isotainer and tanker. 80 drums we can load to 20ft container.

Eagle petrochem guaranty the quality of emulsion with arrangement of international inspector to check the quality and quantity of the bitumen on each shipment during the loading to vessel and controlling the production by QC team via batch test report before shipping. Eagle petrochem guaranty the quality to meet with ASTM/EN 15322:200

Analyze and data sheet of bitumen SS1

src=”https://eaglepetrochem.com/portalimages/userfiles/analysis_of_bitumen_ss1_www.eaglepetrochem.com.jpg”

General description of emulsion asphalt CSS

Bitumen emulsions CSS are usually made by passing the mixture of hot bitumen and water phase between a rotating disc, cone or wheel and a stator. In the emulsification process, hot binder is mechanically separated into minute globules and dispersed in water treated with a small quantity of an emulsifying agent.The water is called the continuous phase and the globules of the binder are called the discontinuous phase. by proper selection of an emulsifying agent and other manufacturing controls, emulsified asphalts are produced in several types and grades:

By choice of an emulsifying agent, the emulsified asphalt may be: (1) anionic – binder globules are electro-negatively charged. (2) Cationic – binder globules are electro-positively charged. Also, by variation in materials and manufacture emulsified asphalts of both anionic and cationic types are made in several grades. Some of these grades and their uses are: (1) anionic – non -Virginia grades RS-2

Tack and seal coat, SS-1h slow set slurry and tack, (2) cationic – Virginia grades CSS-2 tack and seal coat, CSS-1 tack, CSS-1h tack cases-1h two types of slurry (rapid set and slow set) and tack; CSS-2 prime, tack, seal, and cold mix. (Contains 7-12% solvent) because particles having a like electrostatic charge repel each other, asphalt globules are kept apart until the emulsion is deposited on the surface of the soil or aggregate particles. Emulsified asphalts can be used with cold as well as heated aggregates, and with aggregates that are dry, damp, or wet.

The advantage of using emulsion asphalt CSS

No petroleum solvent required to liquefy

Little or no hydrocarbon emissions

In most cases, used with no additional heat

The ability to coat damp aggregate

Can use cold materials at remote sites

Wide variety of emulsion types available today

Application of emulsion bitumen CSS

The advantages of asphalt emulsions CSS are related to their chemical and physical makeup, these advantages lead directly to the applications to the applications in which emulsions are used.

Sealing (CSS-1, CSS-2, m-80, vprime, precoating emulsion)

Slurry surfacing (cqs, cqs-1h, lmcqs, microsystems)

Patching/crack filling (css,css-r, CSS, CSS-r, ss-1)

Fog seal (SS-1, cs’s, cs’s-r, CSS, CSS-r)

Cold mix (CSS, CSS-r, specialty emulsions)

Tack coating (CSS-1, css, SS-1, specialty emulsions).

Dust laying (css, SS-1, specialty emulsions)

Stabilization/ recycling. (css, CSS, specialty emulsions).

Waterproofing / roofing/ home. (Specialty emulsions).

Agriculture. (SS-1, CSS, specialty emulsions).

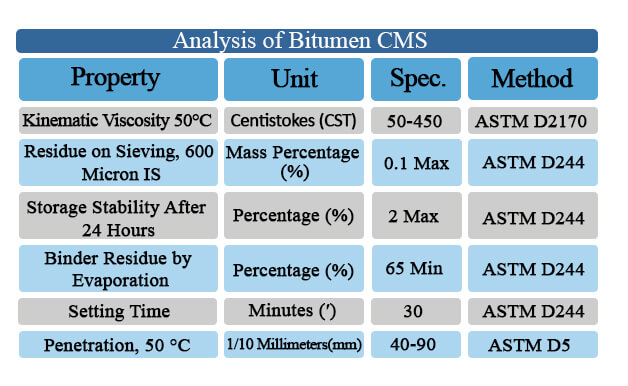

Bitumen CMS Analysis

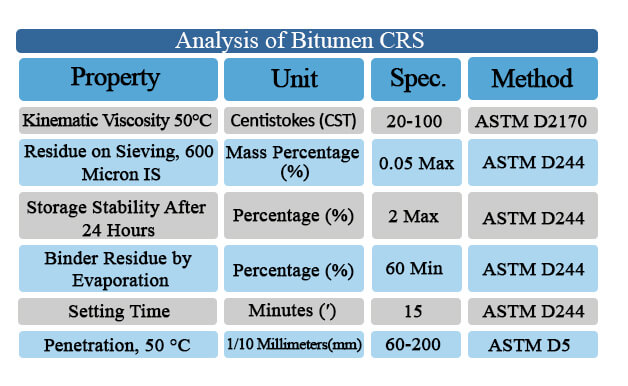

Bitumen CRS Aalysis:

Comments Off on BITUMEN EMULSION with 704 visit