General description of TRAE

TRAE aromatic rubber oil (treated residual aromatic extract, abbreviated as TRAE) is environmental friendly fully aromatic extract oil from solvent extracting process of the residual vacuum distillation which contains polycyclic components (Pac). product contributing to both ease of processing and improved product performance in rubber industry. Using TRAE has some advantage and benefit as below:

Good abrasion resistance

Good low temperature flexibility

Low amounts of waste tires in the process

Good resistance to reversion

According to with international standards (EU 2005/69/ec)

Saving fuel and energy consumption

Extended tires life time

Uses of TRAE (treated residual aromatic extract)

Treated residual aromatic extract (TRAE) carrier oils, plasticizer, diluents filling agent that remain in the final product contributing to both ease of processing and improved product performance in rubber industry.

Packing of TRAE

TRAE rubber process oil is packed in new or used 180 kg drums, iso tank, flexi tanks and bulk shipments. Each 20-foot container takes 80 drum.

Eagle Petrochem Company guaranty the quality of TRAE with arrangement of international inspector to check quality and quantity of TRAE during the loading to vessel and controlling the production by qc by batch test report before shipping. Eagle Petrochem Company guaranty the quality to meet with astm.

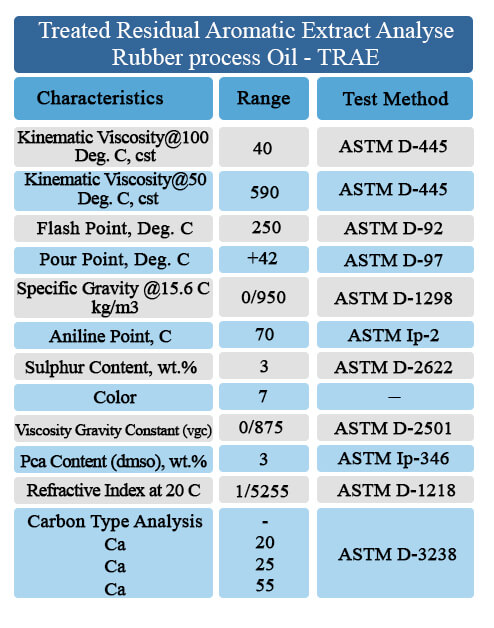

Treated residual aromatic extract analyse:

src=””http://www.eaglepetrochem.com/portalimages/userfiles/ .jpg””

.jpg””

Comments Off on Treated Residual Aromatic Extract(TRAE) with 499 visit